LCD Screen Repair: 5 Tips for a Successful Repair

20-01-2026 • Olvasási idő: 2 min

LCD screens are surprisingly durable, but repairing them requires true precision. One wrong move can damage the screen, lead to additional repairs, and result in unhappy customers. In this blog, we discuss the most common mistakes in LCD screen repairs and how to avoid them.

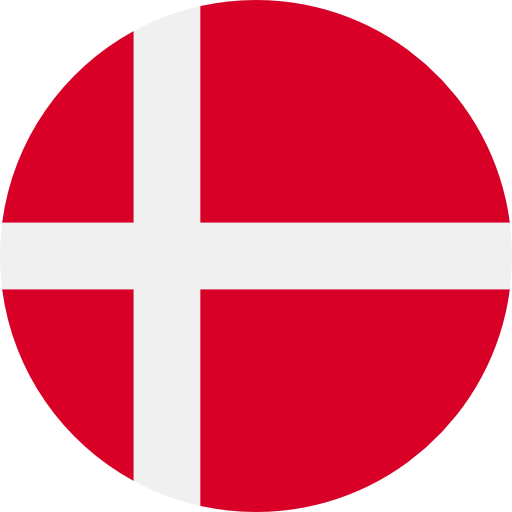

1. Always Use the Right Tools

Much damage is caused by using the wrong tools. Hard spudgers or metal tools can:

- Damage the touch layer

- Crack the glass

- Loosen connectors

Tips for repair technicians:

✔ Use spudgers that aren’t too hard

✔ Make sure screwdrivers are the correct size

✔ Avoid using metal tools on flex cables

2. Watch the Backlight and Adhesive

LCD screens have a backlight that is sensitive to pressure and heat. Mistakes can cause:

- Dark spots or discoloration

- Flickering pixels

- Poor touch response

Tips for repair technicians:

✔ Apply adhesive evenly

✔ Never press too hard in the center of the screen

✔ Make sure the backlight stays in place during assembly

3. Handle Flex Cables Safely

Improperly disconnecting or installing flex cables is one of the most common mistakes.

Consequences:

- Loose connectors

- Intermittent display issues

- Touch problems

Tips for repair technicians:

✔ Check the correct folding direction of the flex cable

✔ Never pull on the cable

✔ Use plastic tools to protect the cable

4. Check the Frame and Chassis

A screen may be damaged from a fall, but the frame can also be warped. A bent frame can cause:

- Breakage during installation

- Pressure points on the screen

- Adhesive that doesn’t bond properly

Tips for repair technicians:

✔ Repair or replace a warped frame

✔ Test the screen separately in the frame

✔ Make sure everything is flat before applying adhesive

5. Test the Screen Before Installation

Issues like dead pixels or backlight problems often only become visible after installation.

Tips for repair technicians:

- Test the screen thoroughly before installation

- Use white, black, and colorful test patterns

- Check touch functionality across the entire screen

Conclusion

LCD screen repair requires attention to detail and the right techniques. Pay close attention to tools, the backlight, flex cables, and the frame, and always test the screen before installation. By working in a structured and careful way, you save time, avoid extra costs, and ensure satisfied customers. With the right parts and knowledge, you can work faster, safer, and more profitably.

Check out our other blog about LCD here.

Stay up to date with the latest developments and updates by reading our blogs and following us on LinkedIn.

HU

HU